Marble Processing Journey

Discover our 10-step precision process that transforms raw marble blocks into exquisite finished masterpieces.

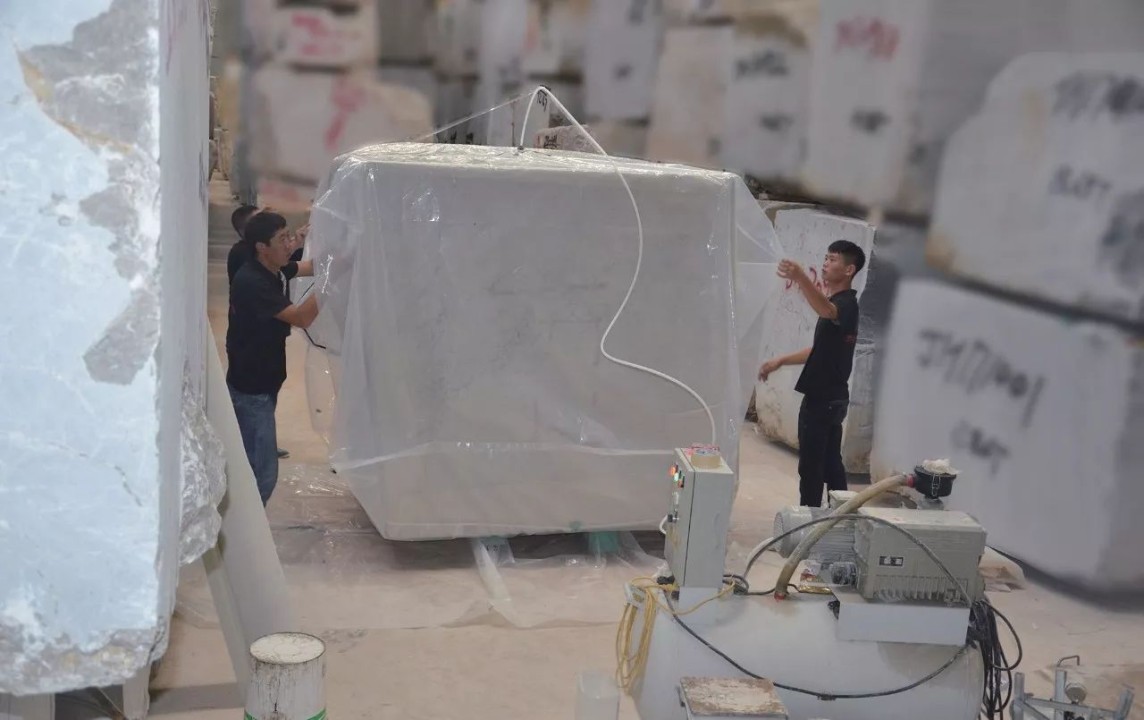

Importing Marble With International Standards

We source premium quality marble blocks from the finest quarries around the world including Italy, Turkey, Greece, and Spain. Each block is carefully selected based on vein patterns, color consistency, and minimum defects.

Key Points:

- Vein patterns and color consistency

- Minimum defects and cracks

- Optimum block size for maximum yield

- Compliance with international quality standards

Our expert team personally inspects each block at the quarry to ensure it meets our stringent quality requirements before shipping.

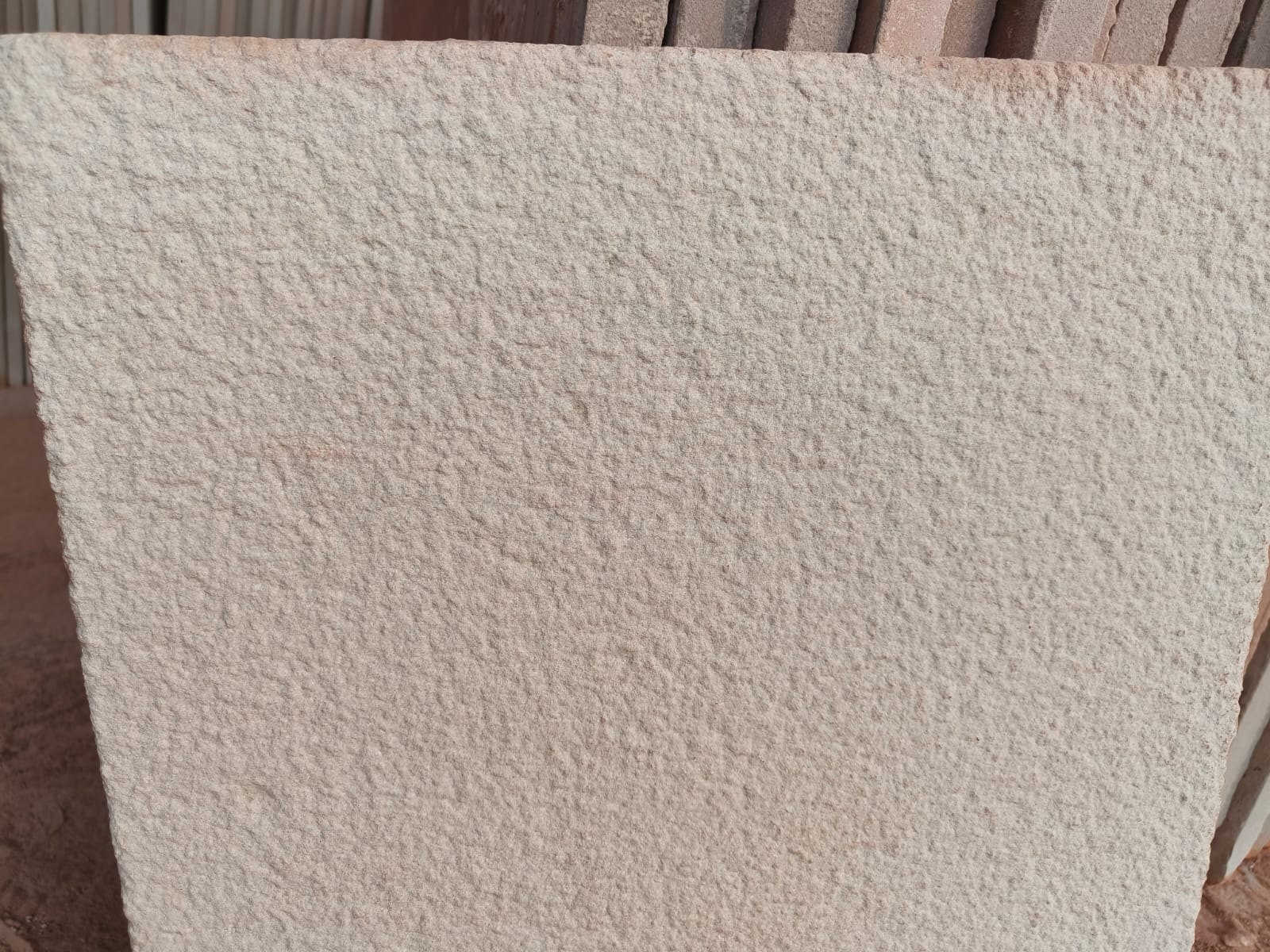

Block Strengthening or Reinforcement Process

Natural marble blocks often have natural fissures and weak points. Our reinforcement process ensures structural integrity before further processing.

Process Includes:

- Epoxy resin injection into natural cracks

- Fiberglass mesh application on weak surfaces

- 24-hour curing process for optimal bonding

- Quality check using ultrasonic testing

This crucial step prevents slab breakage during cutting and ensures longevity of the finished product.

Block Sawing with Gang-Saw

Using state-of-the-art Italian gang-saw machines, we transform reinforced blocks into rough slabs with precise thickness control.

Technical Specs:

- Diamond-tipped blades for precise cutting

- Computer-controlled thickness adjustment (2cm, 3cm, etc.)

- Continuous water cooling to prevent heat damage

- Simultaneous cutting of multiple slabs

Book Matching Slab

For premium projects requiring symmetrical patterns, we offer book matching - arranging consecutive slabs like pages of an open book.

Features:

- Sequential cutting to maintain vein continuity

- Mirror image arrangement for symmetrical patterns

- Expert matching by experienced artisans

- Digital imaging for precise pattern alignment

This technique is essential for creating stunning feature walls, hotel lobbies, and luxury spaces where visual impact is paramount.

Slabs Drying and Pre-Heating

After cutting, slabs undergo controlled drying and pre-heating to prepare for resin treatment and ensure optimal moisture content.

Process Details:

- Temperature-controlled drying chambers (40-50°C)

- Moisture content reduction to below 0.5%

- Uniform heating to prevent thermal shock

- 24-48 hour process depending on slab thickness

Importance:

Proper drying ensures epoxy resin penetrates deeply into marble pores, creating stronger bond and preventing future moisture-related issues.

Double-sided Epoxy Coating

We apply premium epoxy resin to both sides of each slab for enhanced durability, strength, and stain resistance.

Coating Features:

- Industrial-grade transparent epoxy resin

- UV-resistant formulation to prevent yellowing

- Automatic resin spreading for uniform thickness

- Penetrates up to 3mm into marble pores

Vacuum Processing

Vacuum processing ensures complete resin penetration by removing all air from marble pores, resulting in stronger and more durable slabs.

Technical Process:

- High-pressure vacuum chambers (up to 0.9 bar)

- Complete removal of air bubbles and moisture

- Forced resin penetration into microscopic pores

- 2-3 hour vacuum cycle per batch

Grinding with 8 Head Machines

Multi-head grinding machines create a perfectly flat surface in preparation for polishing, ensuring absolute flatness with precision.

Grinding Process:

- 8 sequential grinding heads with diamond abrasives

- Progressive grit sizes from 50 to 800

- Automatic pressure adjustment for uniform grinding

- Water cooling system to prevent overheating

Result:

Each head removes specific material, gradually smoothing the surface and preparing it for final polish. Ensures flatness within 0.2mm tolerance.

Final Polishing Slabs

The final polish brings out the natural beauty and luster of the marble, creating a mirror-like finish that enhances its aesthetic appeal.

Polishing Stages:

- Progressive polishing from 1000 to 3500 grit

- Oxide-based polishing compounds for deep shine

- Multi-stage buffing for mirror-like finish

- Final gloss measurement (95+ on gloss meter)

Stacking of Finished Marble Slabs

Final quality inspection and professional stacking for safe storage and transport, ensuring each slab reaches customers in perfect condition.

Packaging Process:

- Individual inspection under proper lighting

- Protective interleaving paper between slabs

- Corner protectors and edge guards

- Weatherproof wooden crating for export

Traceability:

Each slab receives a unique identification code tracing back to its original block, ensuring complete traceability and quality assurance.

Ready to Experience Premium Marble?

Visit our factory to see these processes in action or contact our experts for a personalized consultation.